How to solve the problem of wave when wood is used when using sander

When the wave pattern is heavy, you can see it directly from the team, the measured thickness, some data changes, and the processed plate can only be classified as a low-grade product. When the wave pattern is light, the intuition is almost nothing, but if it is viewed from the side, it can be seen. If it is experienced, it will be difficult for the customers to experience the past, and the quality of the sheet will be reduced. The reason for the wave pattern is very simple, that is, it is formed by the constant vibration of the sander during work. There are many reasons for the phenomenon of vibration. The improvement is:

1: Try to contact existing models and structures, equip with appropriate motors, and not easy to improve the processing speed and processing strength to facilitate the stability of the machine.

2: Frequent maintenance of sanding machine, timely conditioning, adjustment.

3: Try to use high quality bearings with small errors.

4: Try to buy the whole frame type sanding machine. Although the price is slightly more expensive, the quality of the produced board is relatively improved. Together, some of the transportation should also say that the roller conveyor has a smaller error.

Jiangmen Pengjiang Weisheng Machinery Co., Ltd. inserted a little knowledge, the automatic polishing machine will not damage the surface shape of the workpiece, and the surface rust treatment will be completed once. The automatic polishing machine can: chamfer polishing inside the hole, deburring of metal parts, It does not damage the surface shape of the workpiece and can be widely applied to: medical parts, jewelry and crafts, etc.

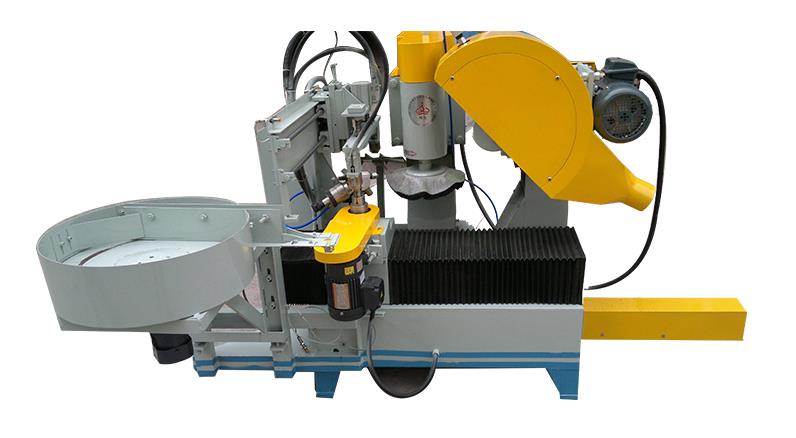

Since its establishment, Jiangmen Pengjiang Weisheng Machinery Co., Ltd. has developed more than 100 semi-automatic and fully automatic polishing and sanding machines, registered 3 trademarks, and applied for more than 50 patents, of which authorized There are three invention patents. Specializing in the production of pressure vessel polishing machine, faucet polishing machine, handle polishing machine, dome polishing machine, round tube polishing machine, outer round polishing machine, elbow polishing machine , plane polishing machine, elbow sanding machine, automatic polishing machine, sand Light machine, disc machine and other equipment.